Product Lifecycle Management (PLM) software is essential for modern product innovation. It oversees a product’s journey from concept and design to manufacturing and service, all the way to disposal or renewal. In a fast-paced global market, where the speed of innovation, compliance with regulations, and teamwork across different locations are crucial, PLM tools have shifted from being optional to mandatory.

By organizing all product-related data and processes, PLM software enhances decision-making, cuts down on redundancies, and ensures that every department—engineering, design, quality, manufacturing, and service—works together effectively. It promotes collaboration across distances, bridges the divide between hardware and software teams, and improves visibility throughout the supply chain. In 2025, as organizations face mounting pressure to innovate sustainably, deliver products more quickly, and remain compliant, PLM solutions are becoming more sophisticated, cloud-based, and integrated with technologies like AI, IoT, and digital twins.

This article explores key concepts, strategic advantages, and emerging trends in the PLM landscape. Whether you’re involved in discrete manufacturing, automotive, aerospace, medical devices, or consumer electronics, recognizing the significance and impact of PLM is vital for selecting and implementing the right system.

What Is PLM Software?

PLM software is a unified platform that manages a product’s information, workflows, changes, and collaborations throughout its lifecycle. It begins with the initial design and continues through prototyping, engineering changes, bill of materials (BOM) control, quality validation, regulatory approvals, manufacturing, customer feedback, and eventual retirement.

Unlike standalone design tools, PLM systems connect people, processes, and technologies. This includes CAD data, part libraries, supplier information, versioning, compliance documents, and even IoT feedback from products in use. The objective is to provide a single source of truth where stakeholders can access current product data and contribute to its progress.

The software often comes in modules, supporting various tasks such as document management, change control, configuration management, cost estimation, and environmental compliance. More advanced systems also offer digital thread capabilities, linking product development data with systems like ERP, MES, CRM, and SCM.

Key Functions of PLM Software

PLM systems generally include the following key features:

- Product Data Management (PDM): Centralized storage for CAD models, drawings, specifications, and BOMs.

- Change Management: Tools for managing Engineering Change Requests (ECRs), Engineering Change Orders (ECOs), and their effects.

- BOM Management: Multi-level and variant BOMs with revision control, validation, and supplier integration.

- Collaboration Tools: Workspaces, commenting features, and access controls for teams across different functions and locations.

- Compliance & Audit Trails: Handling regulatory requirements like RoHS, REACH, ISO 13485, and FDA 21 CFR Part 11.

- Process Workflow Automation: Routing tasks, establishing approval processes, and streamlining development timelines.

- Integration with CAD/ERP/MES: Smooth links between design, planning, manufacturing, and inventory systems.

- These features make PLM a crucial system for modern product companies, helping to shorten time-to-market, eliminate rework, and improve product quality.

Benefits of PLM for Enterprises

Implementing a strong PLM platform offers clear, strategic benefits across the enterprise. Some of the most significant advantages include:

- Accelerated Time-to-Market: PLM software allows engineering and manufacturing teams to work together simultaneously instead of sequentially. With controlled versions of documents and automated processes, organizations can launch products more quickly while minimizing costly errors. This is especially important in industries like consumer electronics and automotive, where getting to market first can make a big difference.

- Improved Product Quality: Centralized data and standardized processes lead to fewer mistakes in documentation, component sourcing, and compliance. Integrated quality management features allow teams to catch design flaws early, monitor non-conformances, and take preventive actions. This results in fewer defects reaching production and ultimately customers.

- Enhanced Collaboration: Modern PLM tools are cloud-based and enable real-time collaboration across engineering, procurement, marketing, and service departments. They eliminate information silos and let distributed teams work from a shared data set. This encourages innovation and speeds up decision-making.

- Regulatory Compliance: In fields like aerospace, medical devices, or electronics, regulatory standards are tightening. PLM software automates documentation, keeps audit trails, and helps ensure that every step in design, manufacturing, and service meets global standards. It streamlines submission and approval for regulators like the FDA, ISO, CE, and others.

- Cost Optimization: By reducing design rework, cutting down on prototype errors, and facilitating smoother supplier collaboration, PLM can realize significant cost savings. It also allows for more precise cost estimates and supports the reuse of parts and designs across various products.

Different industries use PLM in various ways, depending on their product complexity, compliance needs, and innovation speed:

Best Product Lifecycle Management (PLM) Software

1. Siemens Teamcenter

Siemens Teamcenter is a well-established and powerful PLM platform in the enterprise market. It supports the entire product lifecycle, from concept design and development to service and end-of-life. Teamcenter provides a single source of truth for all product data, facilitating collaboration between globally distributed teams in engineering, manufacturing, and procurement.

It integrates with CAD, ERP, and simulation tools to ensure accurate design and faster decision-making. Its modular structure allows companies to use only the features they need, making it suitable for various industries, including automotive, aerospace, and electronics. Teamcenter also uses cloud capabilities and AI insights to improve product change management and compliance.

Features:

- Engineering Bill of Materials (EBOM) and multi-domain BOM support

- Product change and configuration management

- Advanced visualization and 3D mockups

- Role-based access and security controls

- Integration with leading CAD and ERP tools

Pricing: Custom enterprise pricing based on modules and deployment model.

2. Dassault Systèmes ENOVIA

ENOVIA, part of the Dassault Systèmes 3DEXPERIENCE platform, is a highly configurable and collaborative PLM environment. It connects the entire product ecosystem, including design, engineering, sourcing, compliance, and customer feedback, into a single workspace. Its browser-based setup allows users to access product data and workflows from anywhere, which is ideal for global teams.

ENOVIA is popular in complex and regulated industries, such as aerospace and automotive, offering configuration management, digital mockups, and governance. Built on a modular framework, ENOVIA provides tailored apps and industry solutions, allowing organizations to scale as needed.

Features:

- Real-time project tracking and task management

- Collaborative design reviews across global teams

- Product structure and configuration control

- Governance, risk, and compliance management

- Seamless integration with CATIA, SIMULIA, and DELMIA

Pricing: Subscription-based; pricing varies by modules and users.

3. PTC Windchill

PTC Windchill is a leading PLM and Product Management Software that offers built-in capabilities for product data management, change control, and lifecycle tracking. It is designed to scale for both small manufacturers and larger enterprises. Windchill stands out for its open architecture, real-time collaboration features, and integration with Internet of Things (IoT) and augmented reality (AR) technologies.

It helps teams co-develop, validate, and release products in regulated environments, improving traceability and shortening cycle times. Windchill supports concurrent engineering and is well-suited for electronics, industrial, and medical device companies.

Features:

- Integrated change management and configuration control

- Multi-CAD data handling and visualization

- Real-time dashboards and analytics

- Role-based workflows and document control

- IoT and AR integration with ThingWorx and Vuforia

Pricing: Starts at $2,000 per user/year; varies based on modules and user count.

4. Autodesk Fusion Lifecycle

Autodesk Fusion Lifecycle is a cloud-first PLM platform that simplifies product development with configurable workflows and a modern interface. It allows engineering and manufacturing teams to manage BOMs, changes, quality processes, and project timelines from a centralized dashboard.

It integrates with Autodesk tools like AutoCAD and Inventor, enabling design data to flow smoothly through the development pipeline. Fusion Lifecycle supports quick deployment and offers scalable modules for new product introduction, compliance tracking, supplier collaboration, and document control—all without requiring heavy IT infrastructure.

Features:

- Drag-and-drop workflow editor for lifecycle stages

- Quality and compliance modules (e.g., CAPA, audits)

- Supplier and vendor access portals

- Cloud-based change request and approval processes

- Real-time reporting and custom dashboards

- Pricing: Starts at $975 per user/year.

5. Oracle Agile PLM

Oracle Agile PLM is a robust solution for companies needing strong governance, security, and control over complex product data. It supports end-to-end lifecycle processes, from ideation and design to commercialization and post-launch service. Agile PLM is widely used in highly regulated industries like pharmaceuticals, electronics, and aerospace, where managing documentation and version control is crucial.

It fosters real-time collaboration among engineering, manufacturing, and quality teams through secure workflows and structured product hierarchies. Agile PLM integrates well with Oracle ERP and SCM suites.

Features:

- Product portfolio and project management

- Engineering change orders (ECO) and audit trails

- Document and version control with role-based access

- Product quality, compliance, and regulatory features

- Integration with Oracle cloud and on-premise platforms

Pricing: Available on request; pricing depends on deployment scale and modules.

6. Aras Innovator

Aras Innovator is a flexible, open-architecture PLM platform that allows businesses to customize product data and process management while keeping upgrade capabilities intact. Built on a model-based, service-oriented framework, Aras helps organizations in aerospace, defense, and automotive create a secure “digital thread” linking requirements, CAD data, simulations, manufacturing workflows, and service records.

Its upgrade-in-place approach ensures customizations remain through new releases, avoiding complicated migration projects. The platform’s RESTful APIs and low-code tools help develop custom applications, while its community model drives innovation through shared solutions.

Features:

- Model-based data schema for easy customization

- Configuration and change management with full traceability

- Secure collaboration workspaces and role-based access

- Digital thread linking requirements, CAD, simulation, and service data

- Open REST APIs and low-code tools for expanding functionality

Pricing: The core platform is free; enterprise subscription (with support and advanced modules) is quote-based.

7. Arena PLM (a PTC Company)

Arena PLM is a cloud-native solution aimed at high-tech, IoT, and medical device firms that need quick deployment, compliance, and scalability without heavy IT burdens. Using a multi-tenant architecture, Arena connects product records, quality processes, and supply chain collaboration in real time.

This helps fast-growing companies manage design iterations, CAPA activities, and FDA/GxP documentation from a single source of truth. Tight QMS integration means quality events automatically inform product changes, ensuring ongoing improvement and audit readiness. Its modern interface and supplier portals streamline interaction across engineering, operations, and partners.

Features:

- Unified PLM and QMS with closed-loop CAPA and audit trails

- Cloud dashboards for design history files and device master records

- Supplier collaboration portals with controlled access to BOMs and specs

- Automated change approval workflows and electronic signatures (21 CFR Part 11)

- Out-of-the-box integrations with major CAD, ERP, and e-sign tools

Pricing: Starts around $1,500 per user/year; scaling discounts and QMS bundles available.

8. Propel PLM

Propel offers a modern PLM system that integrates product data with CRM software, service, and CPQ processes. This setup is perfect for companies focused on customer-centered product strategies. Since it runs entirely on the Salesforce platform, Propel provides enterprise-level security, global uptime, and low-code configurability, along with pre-built analytics in Tableau CRM.

Marketing, sales, and service teams can access the latest BOMs, revisions, and launch statuses directly within Salesforce, speeding up feedback loops and market activities. Propel’s cloud architecture allows for quick deployment and easy upgrades, while its communities enable real-time collaboration with suppliers and customers.

Features:

- Native Salesforce objects, workflows, and reporting for consistent data

- Product catalogs that synchronize across CPQ, commerce, and service clouds

- Closed-loop customer feedback directly integrated into change requests

- Supplier and partner portals with detailed sharing controls

- Low-code configuration and Lightning UI for fast process adjustments

Pricing: Subscription; contact Propel for user-tier and module-based quotes.

9. Upchain (a PTC Company)

Upchain is a cloud-first PLM designed for small and mid-sized manufacturers needing rich CAD collaboration without the complexity of larger systems. Its browser-based interface allows engineers, suppliers, and non-technical users to review 3D models, markup designs, and manage revisions in real time with no heavy installations.

It connects well with SolidWorks, Inventor, and Creo, automatically syncing metadata and BOM changes to the cloud. Pre-configured workflows for engineering change requests, part approvals, and document control help organizations modernize quickly and affordably.

Features:

- Plug-ins for major CAD tools with automatic version synchronization

- Cloud 3D viewer for markup, redlining, and design feedback

- Multi-level BOM management with “where-used” analysis

- Role-based dashboards for tracking tasks, approvals, and KPIs

- Fast SaaS deployment with ISO-certified security

Pricing: Quote-based; priced per user and functionality tier.

10. SAP PLM

SAP PLM enhances the capabilities of SAP S/4HANA and SAP Digital Supply Chain. It provides global enterprises with a comprehensive digital thread that covers product design, compliance, manufacturing, and after-sales service. By integrating PLM data directly into core ERP processes, SAP enables real-time cost assessments, inventory visibility, and manufacturing insights linked to every design decision.

Its Recipe Development and Specification Management modules are ideal for process industries, while discrete manufacturers use Engineering Control Center to manage multi-CAD data and change impacts across complex BOMs. Built-in analytics on the SAP BTP platform offer predictive insights into project schedules, quality metrics, and sustainability goals.

Features:

- Native integration with SAP S/4HANA, IBP, and MES for seamless operations

- Engineering Control Center (ECTR) for multi-CAD data and visualization

- Product compliance and EH&S modules for global regulatory adherence

- Recipe, formula, and labeling management for process industries

- Built-in analytics and Fiori apps for real-time lifecycle KPIs

Pricing: Enterprise licensing; tailored quotes based on user counts and deployed modules.

11. Omnify Empower PLM

Omnify Empower PLM is a mid-tier lifecycle management platform designed for electronics, medical devices, and industrial equipment companies. It offers built-in functionality for product data management, document control, training compliance, and engineering change workflows. With a user-friendly interface and flexible deployment options (cloud or on-premise), Omnify helps smaller engineering teams manage product complexity without the burdens of larger systems.

Its training and certification tracking features are especially valuable in FDA-regulated sectors, where compliance and audit readiness are essential. Integration with popular CAD, ERP, and CRM systems ensures data continuity across the product lifecycle.

Features:

- Engineering Change Order (ECO) and Document Change Control (DCC) workflows

- Compliance tracking for ISO, FDA, and ITAR requirements

- Integrated training management and employee certification tracking

- BOM and part lifecycle management

- Native CAD and ERP integrations

Pricing: Starts at approximately $1,200 per user/year; pricing varies based on configuration.

12. Centric PLM

Centric PLM is a product lifecycle solution designed for consumer-focused industries like fashion, retail, footwear, cosmetics, and outdoor equipment. With a strong focus on speed-to-market, collection planning, and visual merchandising, Centric helps brands streamline workflows from trend forecasting to store delivery.

Its visually rich UI, mobile-first design, and 3D sample integration make it perfect for design teams managing complex seasonal product lines. Centric also offers PLM-connected tools for material sourcing, supplier collaboration, and production tracking to help consumer brands innovate while meeting margin and sustainability targets.

Features:

- Line planning, seasonal calendar, and assortment management

- Real-time collaboration with suppliers and vendors

- Mobile apps for sample review, quality audits, and design approval

- Fabric, trim, and BOM libraries featuring drag-and-drop functions

- 3D integration with Browzwear, CLO, and other digital design tools

Pricing: Subscription pricing available on request; scaled to company size and modules used.

13. Infor PLM Discrete

Infor PLM Discrete is designed for discrete manufacturing industries such as automotive, aerospace, and industrial machinery. It helps businesses manage part structures, engineering changes, and configuration rules while integrating closely with Infor’s ERP and SCM systems.

Its collaboration modules support supplier engagement, and the built-in compliance tools help manage global regulations like RoHS, REACH, and FDA. With version control, BOM synchronization, and project lifecycle tracking, Infor PLM Discrete offers the depth needed for complex engineering environments while ensuring an intuitive user experience.

Features:

- Complete part, document, and BOM lifecycle management

- Multi-CAD and ERP integration for consistency in product data

- Regulatory and environmental compliance tracking

- Engineering change control with approval workflows

- Supplier management and project milestones monitoring

Pricing: Custom enterprise pricing; available via quote through Infor representatives.

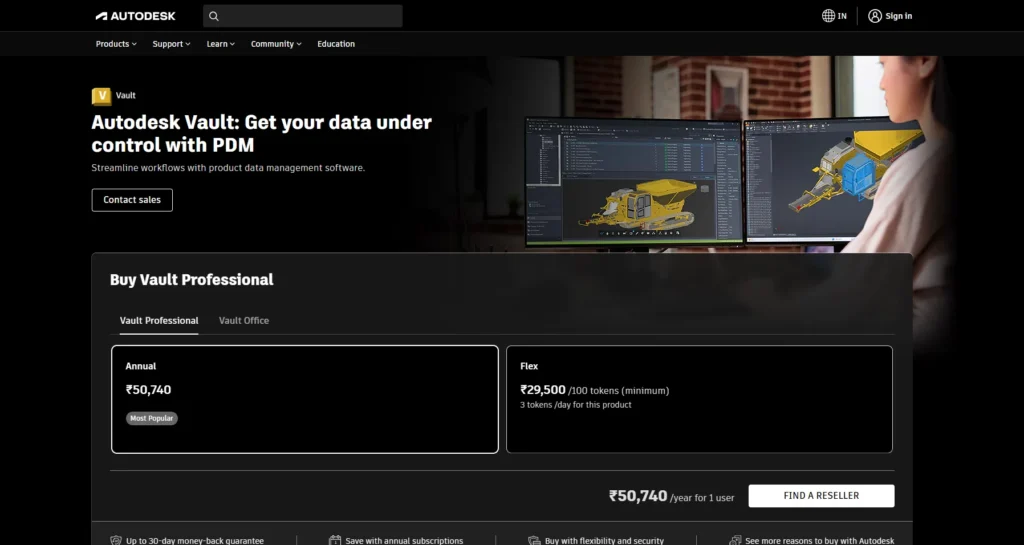

14. Autodesk Vault

Autodesk Vault is a data management solution that improves design collaboration for teams using AutoCAD, Inventor, Revit, and other Autodesk tools. While it is not a complete PLM system, Vault offers solid PDM capabilities and includes many important lifecycle features like version control, access control, and engineering change management.

It is great for small to mid-sized teams who want to organize their design files, reduce rework, and speed up development without implementing an entire enterprise PLM suite. Vault Professional also connects with ERP systems and supports basic workflows for BOM publishing and design release.

Features:

- Secure file versioning and check-in/check-out control

- Multi-user collaboration on design projects

- Automated part numbering, search, and metadata filtering

- Integration with Autodesk Inventor and AutoCAD

- Change order and lifecycle state tracking

Pricing: Starts at about $360 per user per year (Vault Professional).

15. YuniquePLM (by Gerber Technology)

YuniquePLM is PLM software specific to the fashion, apparel, and soft goods industries. It provides extensive support for collection management, tech packs, sample tracking, and vendor communication—all essential for brands managing quick design-to-shelf cycles. Its browser-based interface lets designers and sourcing teams collaborate from anywhere in the world.

Integrated planning calendars and costing tools help speed up development timelines. YuniquePLM also works well with Gerber’s CAD software and automated cutting solutions, making it popular in fashion manufacturing and design settings.

Features:

- Tech pack automation and specification management

- Calendar-based workflow for seasonal planning

- Fabric, trim, and color library management

- Supplier portal for sample submissions and approvals

- Integration with AccuMark and other Gerber production tools

Pricing: Based on quotes; pricing varies by team size and modules.

Cloud-Based PLM vs On-Premise

- One major decision when choosing a PLM system today is whether to go with cloud-based or on-premise deployment. Each option has its benefits and drawbacks.

- Cloud PLM solutions are quickly gaining popularity, especially among small to mid-sized businesses. These platforms require no upfront infrastructure cost, offer fast onboarding, and enable remote collaboration. They are scalable, frequently updated, and usually use a subscription model. Examples include Arena PLM, Propel, and Autodesk Fusion Lifecycle.

- In contrast, on-premise PLM systems provide better control over data security and system customization. They are often favored by large companies in defense, aerospace, or sectors with strict IT rules. However, they require more resources for setup, maintenance, and infrastructure.

- Hybrid models are also emerging—where core functions are in the cloud while legacy systems or sensitive data stay on-site. The best approach depends on your IT strategy, security needs, and growth goals.

PLM vs PDM vs ERP

- It’s easy to confuse PLM with related systems like PDM (Product Data Management) or ERP (Enterprise Resource Planning). Knowing their purposes clarifies integration requirements.

- PDM concentrates on managing CAD files, drawings, and design data. It is a part of PLM, mainly used by design teams.

- PLM expands on PDM by including product development processes, workflows, compliance, collaboration, and change management across departments.

- ERP Software handles transactional business operations such as procurement, inventory, finance, and order management. It typically becomes relevant after product development.

- An ideal product ecosystem includes all three: CAD/PDM for design, PLM for lifecycle management, and ERP for business operations. Integrating them ensures that engineering choices align with manufacturing and financial planning.

Industry Applications of PLM

Different industries use PLM in various ways, depending on their product complexity, compliance needs, and innovation speed:

- Automotive & Aerospace: Focus on configuration management, compliance (e.g., AS9100), and supplier collaboration.

- Medical Devices & Pharma: Prioritize traceability, documentation, and FDA/ISO 13485 compliance.

- Consumer Electronics: Need for quick iterations, version control, and global supply chain coordination.

- Apparel & Fashion: Focus on demand planning, seasonal collections, and digital asset management.

- Industrial Machinery: Deal with complex BOMs, lengthy product lifecycles, and service management.

- Many PLM vendors provide industry-specific solutions or modules that cater to these requirements.

Trends Shaping PLM in 2025

The PLM ecosystem is changing rapidly to keep up with the demands of Industry 4.0, sustainability, and digital transformation. Here are some key trends to watch for in 2025

- AI-Powered Insights: AI and machine learning are being incorporated into PLM systems for predictive analytics, automated classification of parts, and intelligent analysis of change impacts. These features help lessen manual work and hasten decision-making.

- Digital Twin Integration: PLM tools are increasingly connected with IoT and simulation software to support digital twins—virtual models reflecting the physical product. This enables real-time monitoring, proactive maintenance, and better product updates.

- Circular Product Design: Sustainability is now a crucial business goal. PLM platforms are tracking material origins, recyclability, and environmental effects throughout the product lifecycle. Principles of a circular economy are being woven directly into the design and sourcing processes.

- Low-Code Configurability: Vendors are moving towards low-code/no-code platforms, allowing organizations to set up workflows, forms, and dashboards without heavy IT involvement. This leads to quicker deployment and alignment with specific business needs.

- PLM as a Service (PLMaaS): Just as SaaS transformed enterprise IT, PLMaaS models are now available—offering scalable, pay-per-use PLM capabilities with minimal IT overhead. This is especially advantageous for fast-growing startups and mid-sized manufacturers.

Conclusion

Selecting the right PLM software is a strategic investment that directly affects your ability to innovate, operate efficiently, and compete in the long run. As industries move towards more digital, collaborative, and sustainable development models, PLM serves as the foundation for connecting data, tools, and teams throughout the product lifecycle.

Identifying your organization’s specific needs—whether that involves complex supply chains, strict compliance, or rapid design cycles—is vital for making the right choice. Whether cloud-based or suited for enterprises, PLM systems are evolving into smart platforms that not only manage product information but also facilitate better decision-making and future-ready designs.

In the next section, you’ll find 15 top PLM tools ranging from major players like Siemens and Dassault Systèmes to agile innovators like Propel and Arena. Use this list to assess features, pricing, and industry focus as you move forward confidently toward digital product excellence.

FAQs

Q1. What is Product Lifecycle Management (PLM) software?

A1. PLM software helps businesses manage the entire lifecycle of a product—from concept and design to production and retirement—enhancing collaboration and efficiency.

Q2. How do I choose the best PLM software from the list of 15?

A2. Consider factors like your industry needs, team size, integration capabilities, ease of use, and budget when selecting from the 15 best PLM software options.

Q3. Are the 15 best Product Lifecycle Management software tools suitable for small businesses?

A3. Yes, several tools in the list offer scalable solutions with pricing and features tailored to small and mid-sized businesses as well as large enterprises.