Pune, often called the “Oxford of the East” for its top-tier educational institutions, has become one of India’s most prominent industrial hubs. Over the years, Manufacturing Companies in Pune have transformed the city into a center for diverse industries, ranging from automobiles and information technology to electronics and engineering. The city’s strategic location, well-developed infrastructure, and skilled workforce make it an appealing destination for these manufacturing companies.

As the virtue of manufacturing increases so do its applications. Pune, in particular, has become a key player in the country’s manufacturing sector due to its proximity to Mumbai, access to ports, and excellent road connectivity. The growth of manufacturing in Pune has been driven by a combination of government policies, industrial clusters, and continuous innovation by companies operating in the region.

Manufacturing is a sophisticated sector where it uplifts the productivity of both individuals and the economy of a country. It is a versatile field with a huge array of opportunities to help people grow. Manufacturing can uplift the businesses of other industrial sectors. Investing in manufacturing means that a country has positioned itself in a profitable outlook.

Factors Contributing to Pune’s Manufacturing Growth

- Infrastructure: Accessibility through good networks of roads, railways, and location near Mumbai port is appropriate to ensure that manufactured goods are easily transported to the targeted markets.

- Talent: The presence of many universities and colleges creates a quality workforce capable of carrying out complicated operations, especially those related to the development of more sophisticated manufacturing processes.

- Ecosystem: One of the benefits of logistic system and the development of industrial clusters is that they bring together manufacturers and lead to improved operational efficiency.

- Innovation: Cultures adopted by the technical institutions and industries to enhance and develop research create a constant advancement for manufacturing procedures.

- Policy: Policies and incentives such as the manufacturing zones, tax and excise concessions and liberalization policies of the government make Pune a preferred manufacturing hub for both local and international investment.

Key Manufacturing Sectors in Pune

- Automobiles: A strong network of vehicle production, components, and R&D facilities with thousands of employees, highly valuable for exports.

- Heavy Engineering: Large factories that supply equipment and components to industries, especially industries that relate to metallurgy, as well as providing technical personnel in Pune.

- Pharmaceutical Manufacturing: Pune has a strong pharmaceutical sector, producing generic drugs, vaccines, and biotechnology products.

- IT and Electronics Manufacturing: While Pune is known for its IT and software industries, it also has a rapidly growing electronics manufacturing sector.

- Consumer Goods: Manufacturers of home appliances, electronics, and durables get an added advantage of operation in Pune for it locates them well to meet the demands of western India’s large populace.

- Textile and Apparel: Pune is home to a number of textile manufacturing companies, especially those involved in the production of garments and textile machinery. The city has been a traditional center for textile production, particularly in areas such as woolen textiles and synthetic fibers.

- Food and Beverage Processing: The food processing industry is also a major contributor to Pune’s manufacturing sector, with several companies engaged in producing processed food, dairy products, and beverages

- Energy Equipment: Companies are dealing in the manufacturing of engines, generators, and power systems, supplying India’s growing energy demands, and are inclining towards renewable energy products.

- Automation: Implementation of Industry 4.0, manufacturing of industrial automation systems, controls, and smart technologies, locates Pune in the right spot in India.

10 Major Manufacturing Companies in Pune

1. Bharat Forge

One of the established automobile forged product manufacturers and exporters from India is Bharat Forge Industry, which was established in the year 1966. With over a hundred and sixty-five acres of campus in Pune, their annual production has a capability of more than 200000 metric tons. A little over 10 thousand technicians and engineers work at the company’s factories located in Pune. They produce both conventional and precision open and closed die forgings, which can be produced in a variety of sizes ranging from 0.1kg up to 4500kg with accuracy ranging from 0.01mm.

The company earned revenue of 9,200 crores (FY 2023-24) and generated 60% of it from the international market. The Company’s Pune facility, for instance, has more than fifty CNC machines, production lines, and modern metallurgical laboratories. Venturing out from the automobile division, Bharat Forge has entered aerospace, defense, oil and gas, and power divisions, the latter down by 10%, but the defense manufacturing is rising at the rate of 25% per annum.

The company has dedicated 4% of its revenues to R&D where it holds more than 70 patents for its forging technologies. Bharat Forge is recognized among the leading Manufacturing Companies in Pune.

Address: Pune Cantonment, Mundhwa Pune – 411 036

Average Salary: ₹1.2 Lakhs to ₹5.2 Lakhs per year

2. Hindustan Antibiotics Limited (HAL)

Hindustan Antibiotics Limited, which began its journey in 1954 as the first drug manufacturing public sector undertaking of India, functions in a sprawling 283-acre complex in this city. It has a turnover production capacity of 150 million antibiotic tablets as well as 10 million antibiotic vials in a year. Indian company HAL had immediately introduced penicillin production in India and successfully reduced the import level to around 40% in the 1960s. This organization established 12 manufacturing divisions in its plant at Pune, and all of them meet WHO-GMP norms. It has a diversified portfolio of 45 plus products in formulations such as antibiotics, pain relieving products, and anti tuberculosis products.

HAL’s R&D wing has over fifty researchers and employs science to devise cost-effective medicines. The facility increased production to 200% in response to entreaties during the COVID-19 outbreak. From statistics, the firm was in the past providing thirty percent of the government hospital’s antibiotics demand.

Amid financial crises over the years, HAL continues to be a major player for India’s pharmaceutical indigenisation through restructuring and technology modernisation at an estimated cost of ₹ 100 crores. Hindustan Antibiotics Limited holds a significant position among Manufacturing Companies in Pune.

Address: Pimpri, Pune, Maharashtra 411018

Average Salary: ₹99,434 per year

3. Tata Motors

Tata Motors currently has one of the largest automobile production facilities in India, located in Pune, that began its operation in 1945 occupying as much as 800 acres of land. The facility has an estimated strength of about 16,000 workers and has a production capacity of more than 400,000 vehicles per year in the production of passenger vehicles, commercial, and electric vehicles. The Pune plant is highly automated, with 85% output in the body shop area and more than 700 assembly and welding robots. It even has a R & D center worth ₹450 crore with over 4,500 engineers working to build new technologies in the country.

An example of the amenities provided in the facility is an advanced crash test facility that is capable of performing more than twenty-five different crash test configurations. Its factory, that is located in Pune, India, uses 35% of water through recycling and gets 21% of its power from renewable sources.

Today, the plant has used Industry 4.0 technologies in 75% or more of its significant production processes. Their present EV manufacturing line can assemble more than 10,000 EVs per month, which will help meet Tata’s vision of reaching 30% EV sales by 2030. Tata Motors is a key player among Manufacturing Companies in Pune.

Address: Pimpri-Chinchwad, Pune, Maharashtra 411018

Average Salary: ₹10,000 per month, while a senior manager could earn ₹10,90,158 per year

4. Honeywell Automation India Ltd.

Its Pune office in India since 1987 comprises 250,000 square feet and is home to Honeywell Automation’s South Asian operations. 3,500+ engineers and technicians are working in the facility, among them 40% have a master’s degree. It carries out manufacturing and provides more than 200 different automation and control solutions every year that have an export value of US$ 300 million+. It has a 120 crore R&D center in Pune for IIoT solutions with more than 50 patents that can be designed here. Their production systems have Six Sigma quality systems where the defect per million is less than 3.4.

The facility produces various parts that are required in airplanes and needs a tolerance level of up to 0.001mm. Since 2010, Honeywell Pune has measured the energy efficiency at its buildings with smart technologies with a turnover of about 45 percent.

They have their automation products currently installed in 60% of the Indian refineries and 40% of the commercial buildings, while they are increasingly seeing tremendous growth in the health care automation market at 28% annually in the last five years. Honeywell is firmly established as one of the leading Manufacturing Companies in Pune.

Address: 56 & 57, Hadapsar Industrial Estate, Pune, Maharashtra 411013

Average Salary: ₹5.18 lakh to ₹21.41 lakh per year

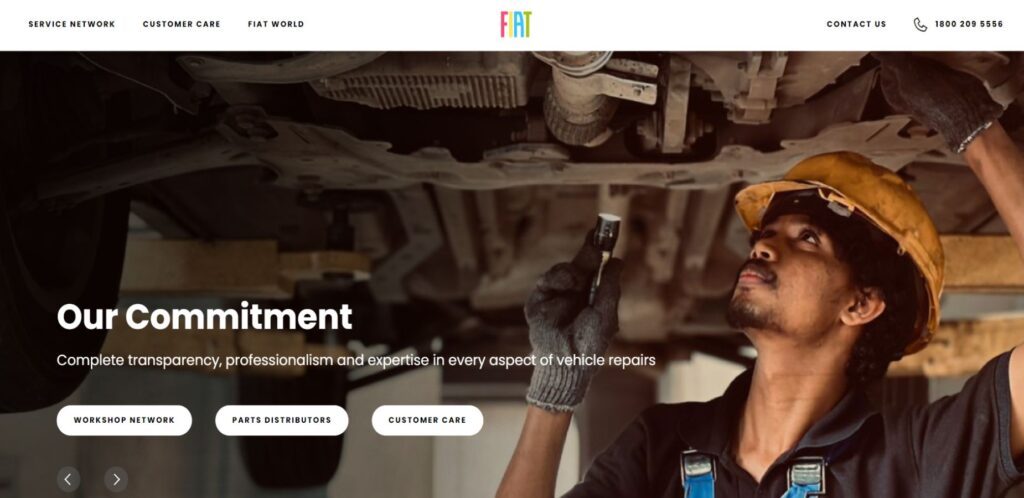

5. Fiat India Automobiles Pvt. Ltd.

The Fiat India Automobiles has a manufacturing plant located at Ranjangaon in Pune, which was initiated in 2007 as a joint venture between FCA India and Tata Motors and is spread across 280 acres with an investment of Rs 4000 crore. This plant has over 3,200 employees, and it has the output capability of manufacturing 160,000 vehicles and 350,000 power trains a year. Currently, the plant is semi-automated at 42% in designing assembly lines incorporating 150-plus robots.

The powertrain they have developed is also responsible for manufacturing engines with some of the best fuel efficiency standards, which have been increasing by 18% over the past decade. It also produces both right-hand and left-hand drives and sells its products in over 15 countries in Asia and Africa. Currently, the rate of water utilization in the manufacturing processes has been estimated to be recycled by 85%.

Here, quality control measures cover more than 120 points, and defects are significantly lower than in other similar companies. It has put ₹250 crore into enhancing the facility to prepare for a shift towards electric vehicle manufacturing in the automotive plant. Fiat India Automobiles is among the prominent Manufacturing Companies in Pune.

Address: Plot No. B-19, MIDC Industrial Area, Ranjangaon, Pune, Maharashtra 412220

Average Salary: ₹3L and ₹7L per year

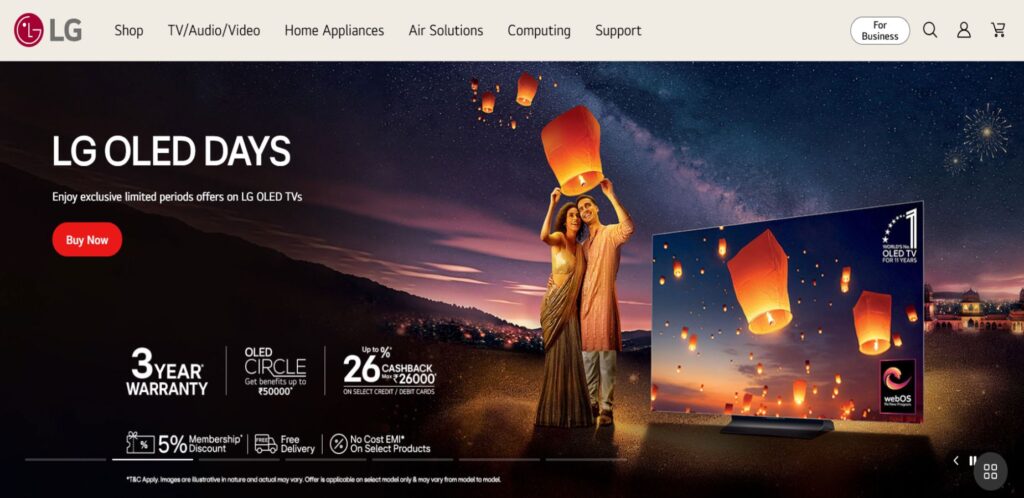

6. LG Electronics

The LG manufacturing plant was set up in the year 2004 and is located in Pune, India, occupying an area of 48 acres at Ranjangaon MIDC. This is an establishment costing ₹1,500 crores and has more than 2,700 employees. The production facility has the following production capacity: 2 million fridges, 1 million washing machines, and 400 thousand air conditioners per year. Companies have attained a high level of automation in manufacturing and currently use over 90 industrial robots in assembly. It uses self-developed environment-friendly refrigerants that are known to lower the effects on the environment by a third compared to conventional refrigerants.

On cost efficiency, their manufacturing process has realized a 25% decrease in power usage starting from 2015. Currently, LG’s factory in Pune supplies more than twenty countries in South Asia, the Middle East, and Africa for a total export value of $240 million every year. The engineering facility ensures increased quality assurance with over 130 test stimuli for every category of product, with a Defect Mean Out of Tolerance of less than 0.5%.

New developments have been made in the past year, such as the ₹100-crore plan to enhance smart appliance production and connectivity, and IoT products into 60% of TTK’s available products. LG is a major name featured among Manufacturing Companies in Pune.

Address: A-13, MIDC Industrial Area, Ranjangaon, Pune, Maharashtra 412220

Average Salary: ₹2 Lakhs to ₹8 Lakhs per year

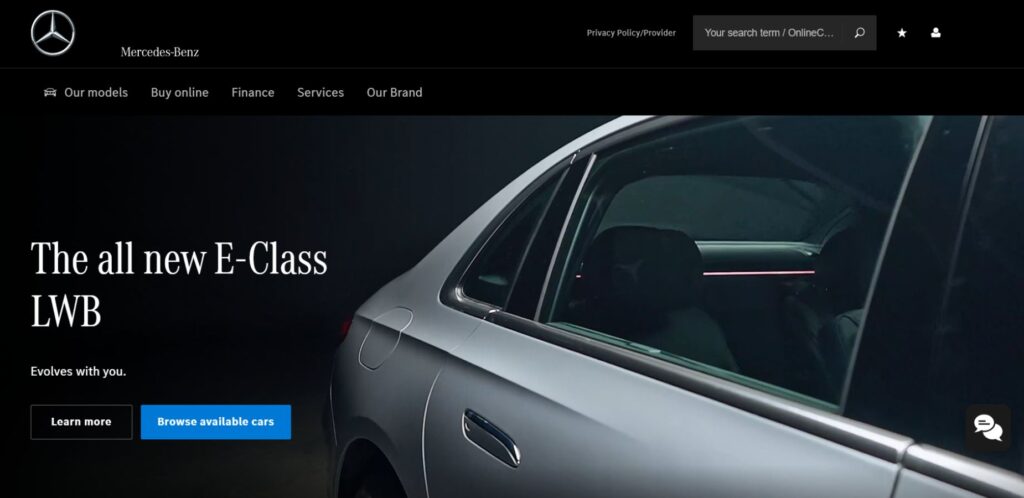

7. Mercedes-Benz India

Mercedes-Benz India has a modern production plant located in Chakan, near Pune, which was inaugurated in December 2009 with an investment of Rs. 2600 crore. The plant measures 100 acres and uses a workforce totaling to 1,400 plus professionals. It can produce twenty thousand cars per annum, and they manufacture thirteen models, which include sedans, SUVs, and AMG vehicles. The plant mostly applies high automation, 90% automation in the paint shop, and it uses a waterborne paint that causes 70% less volatile organic compound emission. In their production processes, they have adopted the use of over sixty robots for assembly activities.

This vehicle has over 1,500 parameters checked individually to maintain high quality at Mercedes-Benz Pune. Therefore, the said facility has attained carbon-neutral production by using sixty percent renewable energy and some carbon offset programs. The amount of ₹400 crores has been spent on localization efforts, which have localized 60 percent of sourcing for some models.

It also houses the Mercedes-Benz India Training Centre, with an investment of ₹200 crores that offers over 240,000 training hours every year to the company’s employees as well as dealer technicians, which will reinforce the company’s dominant position in the luxury car market in India. Mercedes-Benz is a standout among the top Manufacturing Companies in Pune.

Address: E-3, MIDC Chakan Phase III, Chakan, Pune, Maharashtra 410501

Average Salary: ₹6.94 lakh per year

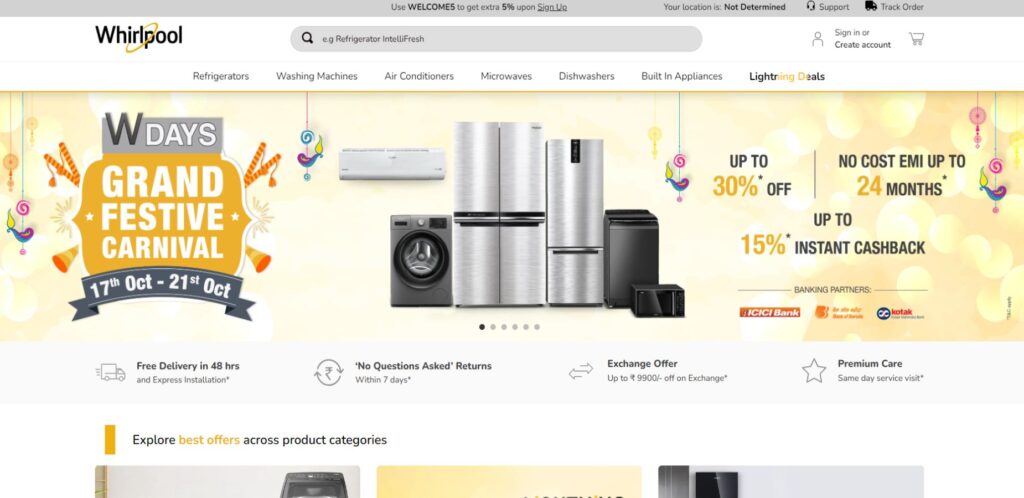

8. Whirlpool of India

Whirlpool manufacturing plant, a part of Whirlpool Corporation, was established in 1996 in a 38-acre area in Ranjangaon MIDC. The plant has a workforce of more than 1,800 people and manufactures 1,200,000 refrigerators and 600,000 washing machines per year. The company has a facility, which costs ₹950 crores, out of which ₹200 crores has been invested in smart appliances in the most recent development. They employed more than 40 automatic production lines with the quality control in real time. It has also realized a 30% decrease in the use of fresh water by implementing closed-loop water recycling systems.

The Whirlpool Pune has adopted IoT and has integrated Industry 4.0 in about 55% of the manufacturing process and has been piloting since the year 2018, thereby increasing productivity by 22%. They have over 120 engineers working at their R&D center, coming up with inventions specific to Indian markets, out of which over 35 have been patented. The facility exports products to over 25 countries in South Asia and Africa; the facility’s export revenue is estimated to be $180 million.

Within Whirlpool, the Six Sigma quality concept is implemented in Whirlpool Pune, with the company’s defect levels in single digits, below 3 PPM. It has energy conservation measures that have cut power use by 25% in the last five years. Whirlpool is recognized as one of the prominent Manufacturing Companies in Pune.

Address: Plot No. A-4, MIDC Ranjangaon, Pune, Maharashtra 412220

Average Salary: ₹24,988 per year

9. Kirloskar Oil Engines Limited (KOEL)

KOL, initially known as Kirloskar Brothers Oil Engine Company Limited, was established in 1946; it has its manufacturing complex in Khadki, Pune, spread over 110 acres of area. This plant has more than 2,200 employees and manufactures more than ninety-five thousand diesel engines per year, from 5 horsepower to hundred horsepower. It has spent more than ₹500 crores on upgrading the facility in Pune with over 70 CNC machines and robotic assembly lines. Their specializations include accuracy in manufacturing, and they can compensate for anything up to 0.005mm.

The R&D centre at KOEL, Pune, has the largest cluster in the country, where more than 150 engineers have launched fuel-efficient and less polluting engine technologies. In the area of energy consumption, the company has achieved efficiency standards and has conserved energy by 28 percent in the last decade. It should be noticed that the quality of their quality management system results in defect rates of below 100 ppm across all products.

KOEL has its engines fitted in 35% of pumping systems used in India’s agriculture and 30% of backup generators in the vital segments. It gets 85% localization in its manufacturing and has bought from more than 200 MSME suppliers in Maharashtra. Recent investments are mainly directed towards compliance with the next emission standard, BS-VI, as well as towards developing solutions with alternative fuels. KOEL stands out as a significant name among Manufacturing Companies in Pune.

Address: 13, Laxmanrao Kirloskar Road, Khadki, Pune, Maharashtra 411003

Average Salary: ₹2,97,306 per year (estimate)

10. Cummins India

Cummins India has several plants in Pune, with their corporate headquarters at Balewadi, which have been located on 90 acres of land since 2003. The consolidated plants occupy 386 acres and employ over 5,000 workers, while the investments made concerning these plants are more than ₹3,000 crores. It can produce more than 200,000 engines every year, ranging from 28 HP to 3500 HP. The facilities currently hold an 80% automation rate in critical assemblies with over 100 industrial robots on board.

Currently, Cummins Pune has 65% Industrie 4.0 solutions across manufacturing processes, and since 2015, productivity has increased by 30%. They own an R&D centre which has more than 1,500 engineers constantly working on devices for emission control, and they met the requirements of BS-VI emissions ahead of schedule. The possibility of assembly is enhanced through a system that permits the production of other parts within tolerances of up to 0.002 millimeters by using computer numerically controlled machines.

Process water at Cummins Pune has been conserved to the extent of 90% with the installation of the water recycling system. Their engines also boast of consuming little fuel, as has been realized to have improved by 15% within the last decade. New investments are worth ₹1,000 crores in hydrogen engine and electrification technologies, aiming for a 30% cut in carbon emissions by 2030. Cummins India is a major contributor among the Manufacturing Companies in Pune.

Address: Cummins India Office Campus, Survey No. 21, Balewadi, Pune, Maharashtra 411045

Average Salary: ₹22,909 per year

Applications of Manufacturing

- Consumer Electronics: The presence of companies like Whirlpool and LG Electronics highlights Pune’s importance in the manufacturing of home appliances and consumer electronics.

- Automation and Technology: Pune is a center for industrial automation, with companies like Honeywell Automation leading the way in producing high-tech solutions for various industries.

- Engineering and Heavy Machinery: Companies like Bharat Forge and Kirloskar Oil Engines have helped establish Pune as a hub for engineering and heavy machinery manufacturing.

- Pharmaceuticals: With companies like Hindustan Antibiotics Limited, Pune plays a crucial role in the production of antibiotics, vaccines, and other pharmaceutical products.

- Automobile Industry: Pune is home to some of the largest automobile manufacturers, making it a significant player in the production of passenger cars, commercial vehicles, and automotive components.

Conclusion

The presence of prominent companies across various sectors, including automobiles, engineering, pharmaceuticals, and electronics, has helped Pune become a vital part of India’s economic growth.

Manufacturing in Pune not only contributes to employment and technological advancements but also plays a significant role in driving innovation across industries. As the city continues to grow and attract investments, its manufacturing sector is expected to remain a key driver of India’s industrial future.

For investors, entrepreneurs, and job seekers, Pune’s manufacturing landscape offers immense opportunities. The city’s commitment to innovation, sustainability, and quality ensures that it will continue to be a major player in the global manufacturing industry for years to come.

FAQs

Why is Pune considered a prominent hub for manufacturing?

Pune’s strategic location near Mumbai, excellent road and port connectivity, well-developed infrastructure, and access to a skilled workforce make it a key hub for manufacturing. The city’s industrial base has grown due to favorable government policies, industrial clusters, and technological innovation.

What role does manufacturing play in Pune’s economy?

Manufacturing is a critical sector in Pune, contributing significantly to the state’s GDP, providing employment to a large section of both skilled and unskilled workers, and driving export activities. It helps in raising the living standards of people, thereby boosting the local and national economy.

How has the manufacturing sector contributed to infrastructure development in Pune?

The growth of manufacturing in Pune has led to improvements in infrastructure, including transportation, roads, and logistics networks. This development enhances the city’s overall industrial output and attracts more businesses to the area.

What types of industries are prevalent in Pune’s manufacturing sector?

Pune’s manufacturing sector is diverse, with industries ranging from automobiles, electronics, and engineering to information technology and pharmaceuticals. The city’s ability to adopt advanced technologies has positioned it as a versatile manufacturing hub.

How does manufacturing contribute to other sectors in Pune?

Manufacturing has a spillover effect on other sectors, such as pharmaceuticals, transport, and logistics. By producing essential goods and technologies, manufacturing supports the development and growth of various industries, further strengthening Pune’s industrial landscape.